Dry Precipitator Inspection

ESPs continue to be excellent devices for the control of many industrial particulate emissions, including smoke from power generation facilities (fired by coal or oil), salt cake collection from black liquor heaters in pulp mills, and catalyst harvesting from fluidized bed catalytic conversion units in refineries to name a few. These devices treat gas volumes from several hundred thousand ACFM (Current Cubic Feet Per Minute) to 2.5 million ACFM in the largest boiler (coal-fired) applications.

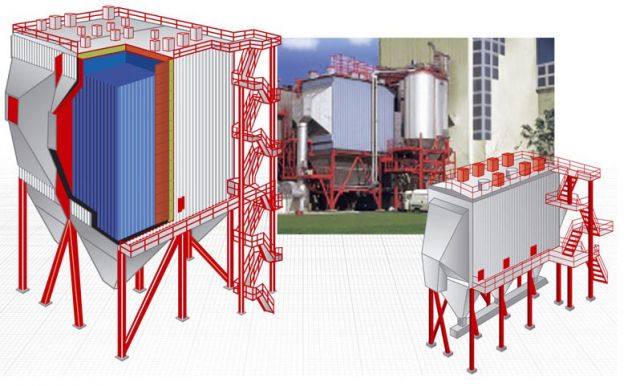

The original parallel plate – charged wire design (described above) has evolved as new, more efficient (and robust) discharge electrode designs have been developed. Today these developments have concentrated on rigid discharge electrodes to which many sharp spikes adhere, maximizing corona output. Transformer-rectifier systems apply voltages of 50-100 kilovolts at relatively high current densities. Modern controls minimize spatter and prevent arcing, preventing component damage. Automatic pounding systems and hopper evacuation systems remove collected particulate matter while online, allowing ESPs to stay in operation for years at a time.